In the contemporary landscape of heating, ventilation, and air conditioning (HVAC) solutions, the choice between purchasing brand new and refurbished Packaged Terminal Air Conditioner (PTAC) units presents businesses with an opportunity to not only save money but also contribute to environmental sustainability. PTAC4Less stands at the forefront of this eco-friendly initiative, offering high-quality refurbished PTAC units that combine economic benefits with a commitment to reducing environmental impact.

Saving Money with Refurbished PTAC Units: A Closer Look at Cost Benefits

The decision to invest in refurbished PTAC units from PTAC4Less translates into direct financial savings for businesses, especially in sectors where climate control is crucial, such as hospitality and healthcare. By choosing refurbished over new, businesses can benefit from reduced upfront costs without compromising on quality or performance.

Refurbished PTAC units from PTAC4Less are meticulously restored to their optimal condition. This process allows PTAC4Less to offer these units at a fraction of the cost of new ones. For instance, while a brand new PTAC unit might be priced at $1,000+, a refurbished counterpart of a similar model and capacity could be available for as low as $300 or less, offering substantial savings.

Purchasing refurbished PTAC units as backups is also a financially prudent strategy. The cost of a room being out of service due to a system failure can be significant, with losses potentially exceeding hundreds of dollars per day. By investing in a couple of refurbished PTAC units at a lower cost, businesses can ensure continuity in their operations, avoiding the downtime and revenue loss associated with unexpected HVAC failures. This strategy is particularly beneficial considering the variable shipping times and potential delays when ordering new units.

Our Comprehensive PTAC Refurbishment Process at PTAC4Less

At PTAC4Less, we’ve refined a meticulous PTAC refurbishment process that revitalizes each unit, ensuring it meets our high standards of quality and performance. This process is designed to not only extend the life of PTAC units but also to deliver a product that is as close to new as possible, at a fraction of the cost.

1. Thorough Inspection

The journey of each PTAC unit at PTAC4Less begins with an in-depth inspection upon arrival. Our skilled technicians conduct a comprehensive examination to assess the unit’s condition, determining its suitability for refurbishment or identifying if recycling is the more appropriate course of action. This initial step is crucial as it sets the benchmark for the quality and potential of each unit we receive.

2. Diligent Repair and Revitalization

Units that clear our initial inspection enter the revitalization phase, where they undergo necessary repairs. This includes the replacement of any faulty components and the resolution of minor issues that may affect performance. In addition to the technical overhaul, every unit is subject to a deep cleaning and deodorizing process, addressing any build-up of dust, debris, and odors that can accumulate over time. Our aim is to ensure that every refurbished unit not only operates flawlessly but also maintains the aesthetic standards expected by our customers.

3. Rigorous Testing for Quality Assurance

Once repaired, the units move to the testing phase, where our expert team performs a series of rigorous quality assurance tests. These tests are designed to challenge the PTAC units under various conditions, ensuring that they meet or exceed operational standards. It is through this extensive testing that we can confidently affirm the reliability of our refurbished units, guaranteeing that they are top-notch and ready for use.

4. Final Inspection for Cosmetic and Functional Excellence

After passing the testing phase, each unit undergoes a final inspection where it is cosmetically enhanced to ensure it not only runs like new but also looks the part. This attention to detail in the final check ensures that when the unit arrives, it presents the professional appearance that aligns with our customers’ expectations. Subsequently, the unit is carefully packaged and prepared for shipping.

Backed by a 1 Year Warranty

Our confidence in our refurbishment process is solidified with a one-year warranty for all refurbished units. This warranty serves as our promise of quality and reliability, providing peace of mind to our customers. Rest assured, these revamped PTAC units are not only optimized to keep your guest rooms comfortable but are also backed by our commitment to excellence and customer satisfaction.

Refurbished PTAC Units: A Step Towards Environmental Sustainability

Choosing refurbished PTAC units from PTAC4Less extends beyond mere cost savings; it’s a meaningful stride toward mitigating the environmental impact of electronic waste. With the United Nations Environment Programme (UNEP) citing a staggering 50 million tons of e-waste generated yearly worldwide, the need for sustainable waste management is more pressing than ever. A significant portion of this waste, if not recycled or reused, can lead to issues such as groundwater pollution, diminished air quality, and an unnecessary drain on raw materials. PTAC4Less actively counters this trend by refurbishing functional PTAC units for continued service, substantially reducing e-waste and sparing fresh resources that would otherwise be used in the production of new units.

Moreover, our refurbishment process rigorously addresses the challenge of refrigerant management. The refrigerants typically found in PTAC units, if released, pose severe risks, including contributing to the depletion of the ozone layer and intensifying global warming. By responsibly handling and recycling these refrigerants, PTAC4Less prevents their potential escape into the atmosphere, aligning our operations with crucial environmental protection efforts.

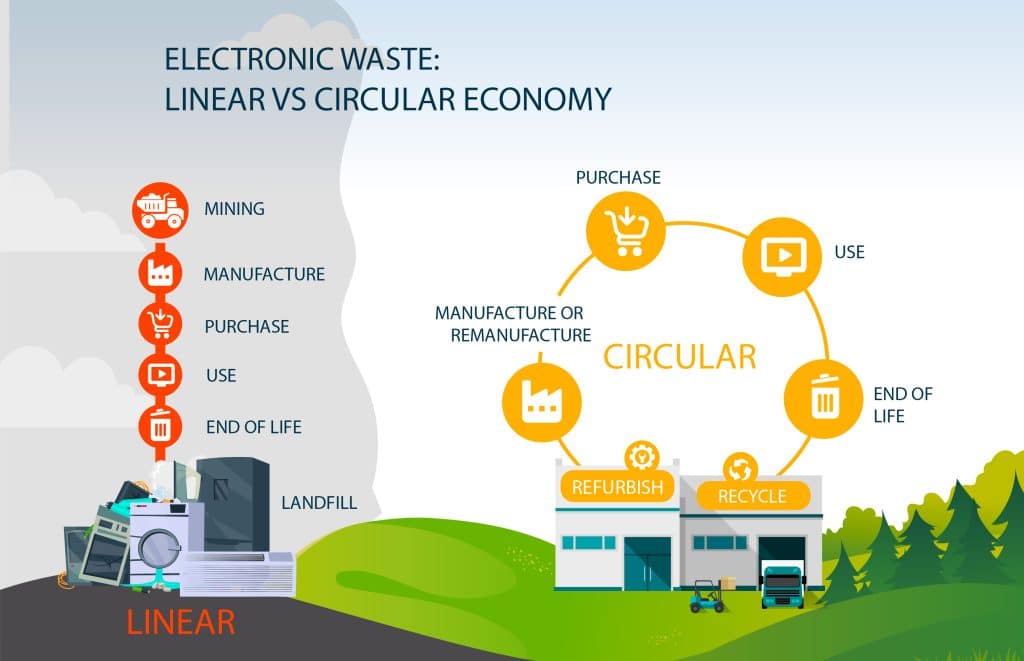

Contributing to a Circular Economy with Refurbished PTAC Units

The practice of refurbishing PTAC units is integral to fostering a circular economy, where products are kept in use for as long as possible, extracting their maximum value before recovery and regeneration. At PTAC4Less, our refurbished units epitomize this approach, demonstrating our resolve to not only provide high-quality climate control solutions but also to partake in an economic system aimed at sustainability and the prudent use of resources.

Refurbished PTAC units from PTAC4Less signify a reduction in the industry’s carbon footprint by necessitating considerably less energy for their restoration compared to manufacturing new units. This process is pivotal in decreasing greenhouse gas emissions and represents a significant environmental savings over the life cycle of each unit. In contributing to a circular economy, PTAC4Less not only ensures that the valuable materials and components within PTAC units are not wasted but also aids in reducing the demand for energy and new materials. This deliberate reduction in resource utilization and waste production is a proactive measure against the escalating issue of climate change, reinforcing our dedication to a sustainable future.

Preserving Critical Resources with Refurbished PTAC Units

Sparing Essential Resources

Refurbishment practices at PTAC4Less drastically reduce the need for core minerals and plastics, which are fundamental to the production of new PTAC units. Mining for these minerals often results in ecological disruption and depletes non-renewable resources. By extending the life of existing PTAC units, PTAC4Less minimizes the demand for new mining operations and the extraction of raw plastics, which typically derive from non-renewable petroleum sources. The reliance on these finite resources is further reduced by salvaging and reusing components and materials from units that are no longer serviceable, thereby promoting the sustainable consumption of our planet’s precious resources.

Conserving Energy and Reducing Emissions

The process of extracting and refining minerals, along with synthesizing plastics, is energy-intensive and generates significant greenhouse gas emissions. PTAC4Less’s refurbishing approach mitigates these impacts by using pre-existing materials, thus conserving the energy that would otherwise be expended in the production of new components. Furthermore, the reduced manufacturing activity results in lower emissions, aligning PTAC4Less with global carbon reduction targets and contributing to a cleaner, more sustainable environment.

Diminishing Environmental Contaminants through PTAC Refurbishment

Mitigating Environmental Contaminants

The mining activities required to obtain core minerals for new PTAC units contribute to water pollution through runoff that carries heavy metals and other toxic substances into nearby water bodies. Additionally, the production processes involved in creating new units release pollutants into the air, including volatile organic compounds (VOCs), particulate matter, and other industrial emissions. PTAC4Less’s refurbished units circumvent much of this pollution by reducing the need for such mining and manufacturing processes.

Promoting Healthier Ecosystems and Communities

By lessening the demand for newly mined materials and the production of new plastics, PTAC4Less helps to curb the pollution that affects both aquatic ecosystems and the quality of the air we breathe. Clean water is essential for wildlife habitats and human communities alike, and air quality has a direct impact on public health. The comprehensive refurbishment process ensures that PTAC4Less plays a pivotal role in maintaining healthier ecosystems and safeguarding community health, demonstrating an ethical commitment to the environment beyond mere regulatory compliance.

Through these actions, PTAC4Less sets a precedent for the sector, highlighting the tangible benefits of a circular economy and its critical role in the sustainable stewardship of our planet.

PTAC4Less: Elevating Standards with Premier Refurbished PTAC Units

At PTAC4Less, we blend commitment to quality with our pledge to sustainability in each refurbished PTAC unit we offer. Our selection rivals new products not only in performance but in our shared responsibility to the environment. Every PTAC unit is rigorously tested and meticulously inspected to guarantee reliability and efficiency. Backed by solid warranties, PTAC4Less stands beside your business, providing a trustworthy option for your climate control needs and the assurance you deserve.

We invite you to explore and shop our line of refurbished PTAC units, where finding the perfect fit for your business is both environmentally responsible and economically smart. By choosing PTAC4Less, you align with a sustainable future, showcasing that high standards in business practices can successfully meet ecological mindfulness. Let’s drive change in the HVAC industry together, proving that the best for your business can also mean the best for our planet.